Fasteners used in manufacturing and repairing valves

Fasteners used in manufacturing and repairing valves

Fasteners, including bolts, nuts, flat washers and spring washers are the common but crucial connection parts in the manufacturing and repairing of all kinds of valves.

In this article, we will talk about the applications of fasteners for all of the valves, instead of just focused on knife gate valves only, as it just took a small part in the big family.

The classification and function of fasteners.

Generally speaking, the fasteners are classified into two categories according to the standards or measuring unit, which are metric fasteners and inch fasteners. Both of them are widely used in valves.

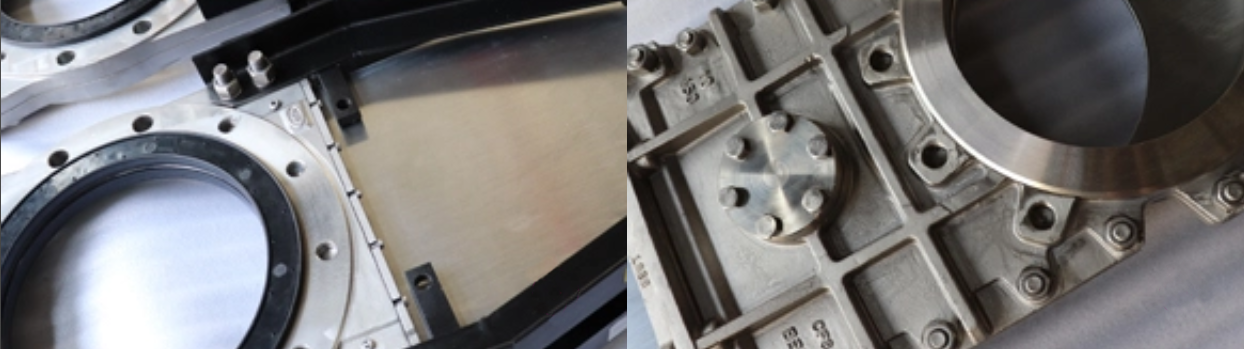

Inch Fasteners Metric Fasteners

Without the bolts and nuts, no valves can be and assembled and connected to the pipelines. So, we all know the importance in manufacturing and installation.

Besides, it is also very necessary in repairing. Bolts and nuts play two important roles: connecting different parts and providing force for it.

Why it is important to check and change the bolts and nut during repairing?

By repairing valves, the old fasteners will be replaced with new ones. Besides matching the thread diameter and length, the most important thing is how to select the correct ones from the aspects of materials and strength.

The bolts and nuts may lose their ability to stretch and clamp if they have been stretched beyond the yield strength in long time.

There may be even corrosion to the bolts. In this way, the strength ability is declined and there is big risk for the safety, especially for the high-pressure valves. Both of these situations make it necessary to change the fasteners when checking and repairing the valves.

How to select the proper fasteners?

Selecting of bolts and nuts, for example the material and their strength, is based upon the materials, pressure of valves and the working conditions. Let's take a look in details:

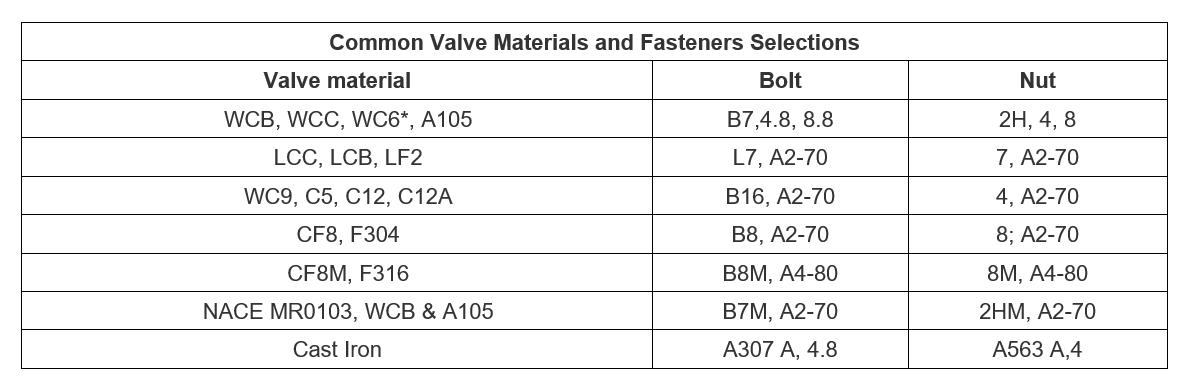

1. For cast iron valves, usually the working pressure is low and the application areas are mainly in water. In this case, the normal standard grade will be ok. For example, ASTM A307 A in Inch or carbon steel Grade 4.8 will be Ok.

2. Then to cast steel and alloy steel valves, such as API and ASME B16.34 valves, the requirements of fasteners are usually according to ASTM A193 (bolts) and A194 (nuts) in inch or carbon steel Grade 8.8, stainless steel A2-70. These are bolts and nuts with high-strength.

3. For ASTM A216 WCB or forged steel of A105, A193- B7 bolts and A194 2H nuts are the most common one for application. But the ASTM A217 WC9, C5, C12 & C12A, B7 bolts are insufficient when there is high temperature in the working condition. In these cases, A193 B16 bolts and A194 4 nuts or stainless steel A2-70 should be used.

4. Austenitic stainless-steel valves (SS304 & SS316) usually require bolts and nuts with the equal materials. The common grades of stainless-steel fasteners used are A193 grade B8 (SS304) and B8M (SS316) with A194 grade 8 (SS304) and grade 8M (SS316), or SS304 A2-70, SS316 A4-80 in metric.

5. When the low temperature is downing to –45° C, A350 grade LF2, ASTM A193 grade L7 bolts and ASTM A194 grade 7 nuts or A2-70 bolts and nuts are commonly used with the valve body of LCB, LCC, etc.

Chart 1. Valves with different materials and the proper fasteners selection

Special consideration must be taken for working conditions including but not limited to:

1. Media or environment contains hydrogen sulfide (H2S).

It is highly corrosive compound, which will cause brittle failure in many hard and strong steels, such as alloy fasteners. So softer and less strong bolts and nuts can be selected. For carbon steel valves, usually A193 B7M bolts and A194 2HM nuts are selected. Because these fasteners have been specially heat-treated to lower the hardness and strength, which makes them suitable to in H2S environments.

2. For higher alloy valves.

There are a number of special high alloy fasteners to select such as Inconel, Hastelloy and Monel. For non-pressure-containing applications like the bolts and nuts used for actuator adapter plates and valve extensions, etc., A307 should be used as a minimum requirement.

3. For the correct application.

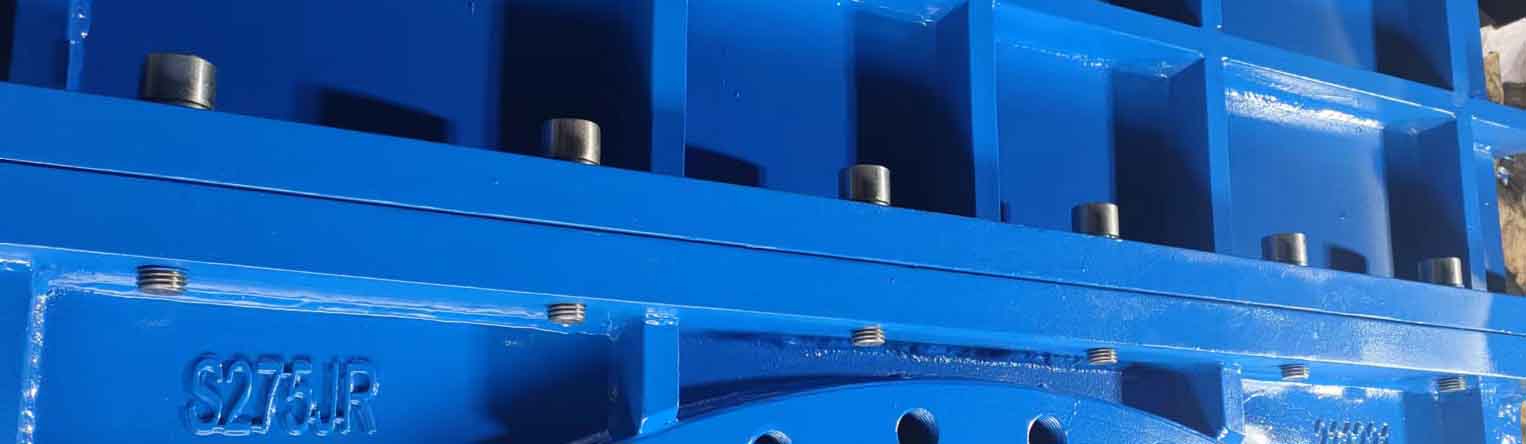

During the valve production, particularly a body and bonnet joint assembly, or body and gland joint for knife gate valves, the bolts must be installed correctly! You should pay much attention to the two important issues below:

3.1 Tightening the bolts using a crossing pattern of bolt tightening,

3.2 Applying the correct torque on the bolts.

The manufacturer of the valve will have published information on bolting torques in many cases. If that information is not available, the document PCC-1-2000 “Guidelines for Pressure Boundary Bolted Flange Joint Assembly” that published by ASME will be a good one for help. This document gives guidance on bolt torques and assembly sequence.

4. Don’t forget to check the special washers

If the needed replaced fasteners contain Belleville washers, which is acting as a live load. Those washers should be checked carefully for damage and replaced them as necessary. Belleville washers will be in different materials. A corrosion-resistant alloy should be chosen if corrosion is an issue in the working condition. Please remember that thick grease can be applied to the washer/bolt assembly to retard corrosion If upgraded washers are not available.

In conclusion:

The fasteners are as important as any other components for valves. They may be the least expensive parts of the valve, but poor-quality fastener will bring big losses. It is crucial important to select the proper fasteners and replace them in certain working period.

The last and the most important: Find a good supplier for fasteners to make sure the materials and mechanical properties are qualified. Here we also put our supplier’s website links: https://www.hb-fasteners.com/product_center If you are interested or looking for more information, you can visit to check.